Photo: Ilze Kuzmina

Author of text: Ilze Kuzmina (Latvian Radio News Service correspondent)

In the coming years, a vaccine created by the company Pfizer against tick-borne Lyme disease could appear on the pharmaceutical market. Meanwhile, research continues at the Latvian Biomedical Research and Study Centre, the results of which could lead to even more effective vaccines against this disease.

Lyme disease, caused by bacteria called Borrelia, is the most common tick-borne infection in the Northern Hemisphere. It affects more than 14 percent of the world’s population. According to data from the Center for Disease Prevention and Control (SPKC), more than 500 cases were detected in Latvia last year, which is twice as many as in 2023. Untreated Lyme disease can cause joint pain, heart palpitations, and other health problems. Kalvis Brangulis, a leading researcher at the Biomedical Research and Study Centre, says that up to 130 different types of proteins are found on the surface of this Borrelia. Some of these proteins could be the most effective in a vaccine because they are the first to interact with the host organism they have entered and are capable of generating antibodies against Lyme disease.

“This means they are the ones recognized by the host organism, for example, the human body. And then the body develops antibodies against them. Therefore, it is logical that surface proteins are interesting to study [to find out] if they can be used as vaccine antigens. For example, the protein I studied, the CspZ protein, was exactly like that. It is on the surface, that is known, it had been experimentally tested, and then it was interesting to understand if it could be used for a vaccine,” Brangulis said.

The aforementioned CspZ protein, which the researcher has studied the most, helps bacteria evade attacks from the human immune system. The vaccine that Pfizer could soon license, on the other hand, was created from another Borrelia surface protein discovered at the end of the last century. At that time, the first vaccines also emerged, though they were only available for a few years. Doubts had arisen about their safety, which later proved to be unfounded. Now, the upcoming vaccine is made from the same protein; however, it has been slightly modified, meaning the vaccine has been improved.

Brangulis has also aimed to improve the CspZ protein he studied, making it more useful for antibody production. The protein needs to be stabilized by slightly changing its structure to ensure it will work as expected in a vaccine. “This is called structural vaccinology, and it is actually becoming quite a popular direction, where modifications are attempted in this way to improve the protein structure,” the researcher stated.

With Pfizer’s upcoming vaccine, three booster shots might be needed to achieve immunity, but if the protein studied by Brangulis were used for the vaccine, no more than two vaccinations would be required. At least, this is confirmed by data obtained by partners in the United States, who tested antibodies formed from the CspZ protein on mice. “And that shows that this protein would indeed potentially be better than the one currently being developed,” said Brangulis.

However, first, to understand what this protein is like, its three-dimensional structure had to be created: “Doing this for a protein is complicated because you can’t just look at it under an optical microscope and see it, because the protein is too small to be seen in an optical microscope. Therefore, X-rays must be used. But to use X-rays, crystals must first be obtained from that protein.”

Once the crystals are formed, they are frozen with liquid nitrogen and sent to a foreign research institution where a synchrotron is available: a particle accelerator in which electrons move at nearly the speed of light, creating very powerful X-rays that help determine the overall structure of the protein.

One of the most time-consuming processes in the researcher’s work is obtaining the proteins. They are grown in bacteria. Afterward, they are purified from other proteins unnecessary for the study to obtain pure Borrelia protein.

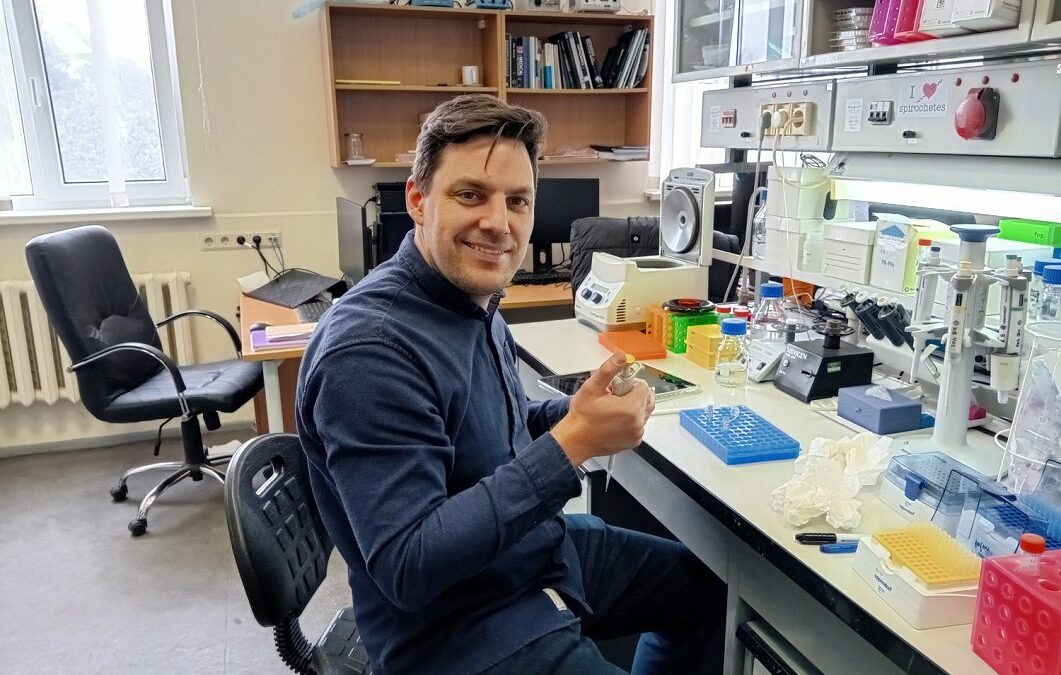

During the conversation, the researcher continued his work periodically: he placed tubes containing the protein into a special centrifuge. He explained: “There are these tubes, they have a membrane, and that membrane lets through everything smaller than a specific size. For example, I know that my protein is larger, and so it turns out that it doesn’t go through the membrane. If I centrifuge it now, the entire solution flows through, but my protein doesn’t: it turns out that it becomes more concentrated,” Brangulis said. The centrifuge is the final stage for purifying and concentrating the protein. Before that, the researcher had already purified them in a chromatograph.

Brangulis has been working in this field for more than 15 years. He managed to obtain the first Borrelia protein structure in 2010. On average, it takes about a year to obtain the structure of one such protein, but Brangulis has already obtained 60 Borrelia protein structures and plans to continue his research.